Implemented isolation design between transmission and mold

NEWTOP-1250WT is an efficient and intelligent paper cup jacket machine

Implemented isolation design between transmission and mold

NEWTOP-1250WT is an efficient and intelligent paper cup jacket machine

Adopting an open intermittent segmentation design, gear transmission and longitudinal axis structure

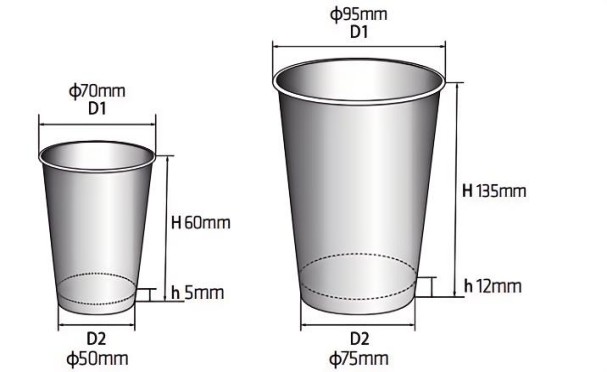

This machine adopts spray lubrication and PLC control system, equipped with photoelectric fault detection and servo feeding to ensure stable and efficient operation, with a maximum speed of 120 pcs/min. Suitable for the production of 8-44OZ cup sleeves, with good insulation effect, ideal equipment for hot beverage cups, instant noodle bowls, coffee cups, etc.

.png)

.png)

.png)

|

Model |

NEWTOP-1250WT |

|

Weight |

2600kg |

|

Machine encasement dimension |

2700 x 1300 x 2100mm |

|

Rated power |

Three-phase, 380V, 5KW |

|

Compressed air |

0.6-0.8MPa, 0.4 m3 /min |

|

Max Capacity |

120pcs/min |

|

Paper materials |

Gray board/White board |

|

Paper thickness |

0.2825-0.4075mm |

|

Product range |

(D1)φ90-150mm (H)70-110mm (D2)φ80-120mm (h)5-12mm |

| Grease Lubrication |  Hand Movement11 Hand Movement11 |

| Ultrasonic |  Ultrasonic Ultrasonic |

| Airborne detection |  Collect table Collect table |

| Piping |  Single line pipeline Single line pipeline |

8oz-44oz Paper Cup Size

150pcs/min Max Capacity

70pcs/min Max Capacity