The isolation design between the transmission mechanism and the forming mechanism has been achieved.

NEWTOP-YB150 is a stable, easy to clean and maintain paper cup flattening machine

The isolation design between the transmission mechanism and the forming mechanism has been achieved.

NEWTOP-YB150 is a stable, easy to clean and maintain paper cup flattening machine

Adopting grease gap automatic lubrication

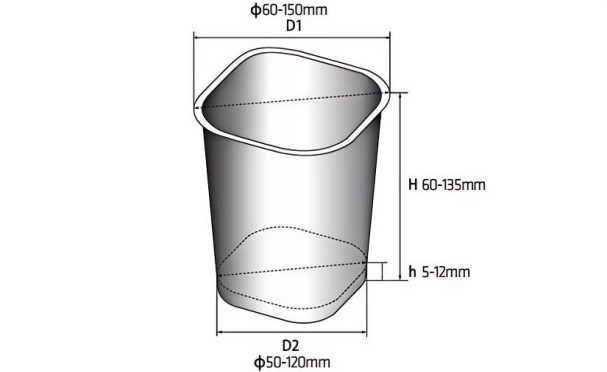

All transmission components are installed in the main frame below the workbench, and the upper device is placed around the indexing turret according to the molding process. The machine is controlled by PLC and the entire process is monitored by photoelectric sensors. This machine is suitable for flattening the edges of paper cups with a diameter of Ø 60-Ø 120mm.

|

Model |

NEWTOP-YB150 |

|

Weight |

2000 kg |

|

Machine encasement dimension |

2150 x 1450 x 2200mm |

|

Electrical specifications |

Three-phase, 380V, 6.5KW |

|

Air supply specifications |

0.4~0.6MPa, 0.4m³/min |

|

Max Capacity |

120pcs/min |

|

Paper specifications |

(D1)φ60-150mm (H)60-135mm (D2)φ50-120mm (h)5-12mm |

| Grease Lubrication |  Automatic Automatic |

| Ultrasonic |  Ultrasonic Ultrasonic |

| Hot Air Generator |  Bottom Bottom |

| Hot Air Generator |  Broadside Broadside |

| Paper Cup Lubrication |  Cup bottomlubr ication Cup bottomlubr ication |

300X200X400-500X400X700 Carton specifications

30Cartons/Hr Max Capacity